Design and Testing of On-Board and Special Equipment and Systems

Head of the department

Ilya V. CHULKOV

Labs

- Spacecraft Hardware and System Design. Head: Konstantin V. ANUFREICHIK

- Microsatellite Experiments Planning and Support. Head: Igor V. KOZLOV

- Spacecraft Hardware and System Testing. Head: Natalya I. CHUMAK

- Robotic Systems for Planetary Explorations. Head: Tatiana O. KOZLOVA

- Design Engineering and Simulation. Head: Alexey A. KONOVALOV

- Scientific Payload Design and Testing and Support of Manned Module Science

- Dedicated Onboard Equipment for Space Experiments. Head: Andrey V. BONDARENKO

Новости

Head of the department

Ilya V. CHULKOV

Labs

- Spacecraft Hardware and System Design. Head: Konstantin V. ANUFREICHIK

- Microsatellite Experiments Planning and Support. Head: Igor V. KOZLOV

- Spacecraft Hardware and System Testing. Head: Natalya I. CHUMAK

- Robotic Systems for Planetary Explorations. Head: Tatiana O. KOZLOVA

- Design Engineering and Simulation. Head: Alexey A. KONOVALOV

- Scientific Payload Design and Testing and Support of Manned Module Science

- Dedicated Onboard Equipment for Space Experiments. Head: Andrey V. BONDARENKO

Themes

- design of onboard and control and testing equipment for space research;

- equipment manufacturing;

- onboard equipment testing for external factors’ effects.

In general

The Laboratory of R&D Support of Spacecraft Autonomy (later - the Department) was established at IKI in 1973. Its tasks included engineering implementation, service and support of scientific projects onboard spacecraft. Both the laboratory and later the department were headed by Dr. Evgeny M. Vasiliev, Lenin Prize laureate (1934-2002). Afterwards the Department was headed by V.F. Babkin (acting head), Dr. O.P. Klishev. In 2008, the instrument engineering direction at the Institute was headed by Ilya V. Chulkov. The department was named the Department for Design and Testing of On-board and Special Equipment and Systems.

For all that time the staff maintained a full working cycle with scientific equipment systems, which included design documentation, tests at IKI and production plants, at the cosmodrome, and then operation of scientific payload aboard Mars, Venus, Phobos interplanetary stations, Prognoz spacecraft, automated universal orbital stations AUOS, high-altitude atmospheric and astrophysical probes (VZA, VZAF-S), Science spacecraft, etc. A division for the development of onboard digital information systems was created. The Department also developed a complete set of operating and maintenance documentation for scientific equipment and control and testing devices (KIA). The staff members participated in acceptance of scientific equipment, all types of its ground tests and in control operations during the flight.

Hardware development

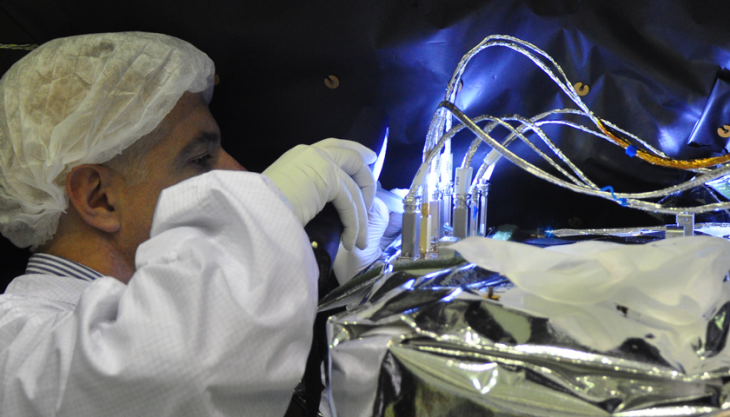

Today, the functions of the design department are the development, support of manufacturing, ground and flight testing of onboard scientific instruments for space research. Also, the designers of the Department develop control and testing equipment for all types of ground tests of both onboard instruments and complex scientific and service systems.

Every year, the Department develops several dozen onboard instruments and ground testing systems. The domestic element base is given priority. All the main interfaces for the onboard equipment are utilized: multiplex exchange channel MKO, Spacewire, interfaces based on RS-485/422 and LVDS standards. There are developments in the operating of various types of drives and heaters, query of telemetric digital and analogue sensors.

Instruments building

Onboard devices and cables, as well as equipment for ground testing of onboard devices can be built at IKI’s Pilot production facility.

The machining section is furnished with modern three- and five-axis machining centers, new lathes, electric-spark copy-piercing machines, laser cutting and engraving machines and many others.

The assembly section enables mounting circuit-boards of devices, connecting cables and units.

In 2020, more than 6,000 components and assemblies were manufactured at the IKI Pilot production facility.

Testing

All types of tests, which expose onboard equipment to the various effects of the external factors, can be carried at IKI’s Testing and Control Station:

- climatic testing section;

- vacuum testing section;

- mechanical testing section (vibration and shock effects, linear overload);

- electromagnetic compatibility and electrostatic discharge testing section.

Every year, more than a hundred devices undergo various tests in IKI.

Auxiliary sections

There are a wide range of auxiliary sections in IKI: Meteorological Service, Technological Service, Quality Control Service, Hardware Inspection and Certification Group, Technical Department, Archived Documents Division, Technical Documents Library.

Works are carried out under the control of the Quality Control Service and the acceptance department of the Ministry of Defence of the Russian Federation.